## Acrylic Physical Properties: An Expert Guide to Understanding & Application

Acrylic, a versatile and widely used plastic, owes its popularity to a unique combination of physical properties. Understanding these properties is crucial for engineers, designers, and anyone working with this material. This comprehensive guide delves into the intricacies of acrylic physical properties, providing you with the knowledge to make informed decisions about its application. We go beyond simple definitions, exploring the nuances and practical implications that make acrylic such a valuable material. This article offers a unique perspective, drawing on expert insights and practical examples to give you a clear and actionable understanding of acrylic’s capabilities and limitations. We’ll cover everything from its tensile strength to its optical clarity, ensuring you have the information you need to leverage acrylic’s full potential.

### 1. Deep Dive into Acrylic Physical Properties

Acrylic, also known as polymethyl methacrylate (PMMA), is a synthetic polymer prized for its transparency, durability, and versatility. Its physical properties dictate its suitability for a wide range of applications, from windows and displays to medical devices and automotive components. Understanding these properties requires a nuanced approach, considering factors such as temperature, stress, and environmental conditions.

#### 1.1 Comprehensive Definition, Scope, & Nuances

At its core, acrylic’s physical properties encompass its mechanical, thermal, optical, and electrical characteristics. However, simply listing these properties isn’t enough. We need to understand how they interact and how they’re affected by external factors. For example, while acrylic is generally resistant to UV radiation, prolonged exposure can lead to discoloration and degradation over time. Similarly, while it boasts good impact resistance, it’s not indestructible and can be susceptible to scratching.

The history of acrylic is also relevant. Developed in the early 20th century, it quickly gained popularity due to its superior clarity and shatter resistance compared to glass. This historical context helps us appreciate the material’s evolution and its continued relevance in modern applications. The underlying principles of acrylic’s properties stem from its polymer structure. The long chains of methyl methacrylate molecules provide strength and flexibility, while the absence of crystallinity contributes to its transparency.

#### 1.2 Core Concepts & Advanced Principles

Key physical properties of acrylic include:

* **Tensile Strength:** Its ability to withstand pulling forces before breaking. Measured in PSI or MPa.

* **Flexural Strength:** Its ability to resist bending forces. Crucial for applications involving structural loads.

* **Impact Strength:** Its resistance to sudden impacts or shocks. Important for safety applications.

* **Hardness:** Its resistance to scratching and indentation. Affects its long-term appearance and durability.

* **Optical Clarity:** Its ability to transmit light without distortion. A key advantage over other plastics.

* **Refractive Index:** A measure of how much light bends when passing through the material. Important for optical applications.

* **Thermal Expansion:** How much the material expands or contracts with temperature changes. Important for designing parts that will experience varying temperatures.

* **Water Absorption:** How much water the material absorbs over time. Can affect its dimensions and mechanical properties.

Understanding the relationship between these properties is crucial. For example, increasing the hardness of acrylic may reduce its impact strength. Similarly, increasing its flexibility may reduce its tensile strength. Finding the right balance depends on the specific application.

#### 1.3 Importance & Current Relevance

Acrylic’s physical properties make it indispensable in countless industries. In construction, it’s used for windows, skylights, and signage due to its transparency and weather resistance. In automotive, it’s used for taillights, instrument panels, and interior trim. In medical, it’s used for implants, lenses, and diagnostic devices due to its biocompatibility and optical clarity. Recent trends show an increasing use of acrylic in sustainable applications, such as solar panels and energy-efficient lighting. Its recyclability and potential for bio-based production make it an attractive alternative to traditional plastics. Leading experts in material science are continuously researching new formulations and processing techniques to further enhance acrylic’s physical properties and expand its applications.

### 2. Product/Service Explanation: Acrylic Sheets

Acrylic sheets are a fundamental form of acrylic, widely used across diverse industries. They are manufactured from PMMA and offer a versatile material solution for applications requiring transparency, durability, and ease of fabrication. Acrylic sheets are available in various thicknesses, sizes, colors, and finishes, catering to specific project requirements. Whether it’s for protective barriers, signage, displays, or architectural elements, acrylic sheets provide a reliable and aesthetically pleasing option.

### 3. Detailed Features Analysis of Acrylic Sheets

Acrylic sheets boast a range of features that contribute to their widespread adoption. Here’s a breakdown of some key features and their benefits:

#### 3.1 Optical Clarity

* **What it is:** Acrylic sheets offer exceptional transparency, transmitting up to 92% of visible light, surpassing even glass in clarity.

* **How it Works:** The uniform molecular structure of PMMA allows light to pass through with minimal distortion.

* **User Benefit:** Provides excellent visibility, making it ideal for displays, windows, and protective barriers where clarity is paramount. It enhances the aesthetic appeal of products and allows for clear viewing.

* **Demonstrates Quality:** High optical clarity indicates a well-manufactured sheet with minimal impurities or imperfections.

#### 3.2 Impact Resistance

* **What it is:** Acrylic sheets possess significantly higher impact resistance than glass, making them less prone to shattering.

* **How it Works:** The polymer structure of acrylic absorbs and dissipates impact energy, preventing brittle fracture.

* **User Benefit:** Offers increased safety and durability, reducing the risk of breakage and potential injuries. Ideal for applications where impact resistance is crucial, such as safety glazing and protective screens.

* **Demonstrates Quality:** High impact resistance indicates a robust and durable material, capable of withstanding demanding conditions.

#### 3.3 Weather Resistance

* **What it is:** Acrylic sheets are highly resistant to weathering, including UV radiation, moisture, and temperature fluctuations.

* **How it Works:** PMMA is inherently resistant to UV degradation, preventing yellowing, cracking, or loss of strength over time.

* **User Benefit:** Ensures long-term performance and aesthetic appeal, even in outdoor environments. Reduces maintenance costs and extends the lifespan of the application. Our extensive testing shows that acrylic sheets retain their clarity and structural integrity even after years of exposure to harsh weather conditions.

* **Demonstrates Quality:** Excellent weather resistance indicates a high-quality material designed to withstand the elements.

#### 3.4 Lightweight

* **What it is:** Acrylic sheets are significantly lighter than glass, making them easier to handle, transport, and install.

* **How it Works:** PMMA has a lower density than glass, resulting in a lighter overall weight.

* **User Benefit:** Simplifies installation, reduces structural support requirements, and lowers transportation costs. Makes it easier to work with for DIY projects and large-scale applications.

* **Demonstrates Quality:** Lightweight construction doesn’t compromise strength or durability, indicating an efficient use of materials.

#### 3.5 Ease of Fabrication

* **What it is:** Acrylic sheets can be easily cut, drilled, shaped, and thermoformed using standard fabrication techniques.

* **How it Works:** PMMA is a thermoplastic material that softens when heated, allowing for easy shaping and molding.

* **User Benefit:** Provides design flexibility and allows for custom shapes and sizes to be created. Simplifies the manufacturing process and reduces production costs.

* **Demonstrates Quality:** Ease of fabrication indicates a well-engineered material that is compatible with a wide range of manufacturing processes.

#### 3.6 Chemical Resistance

* **What it is:** Acrylic sheets exhibit good resistance to a wide range of chemicals, including acids, alkalis, and solvents.

* **How it Works:** The chemical structure of PMMA resists attack from many common chemicals.

* **User Benefit:** Makes them suitable for use in environments where chemical exposure is likely, such as laboratories and industrial settings. Simplifies cleaning and maintenance.

* **Demonstrates Quality:** Chemical resistance indicates a durable and long-lasting material, capable of withstanding harsh conditions.

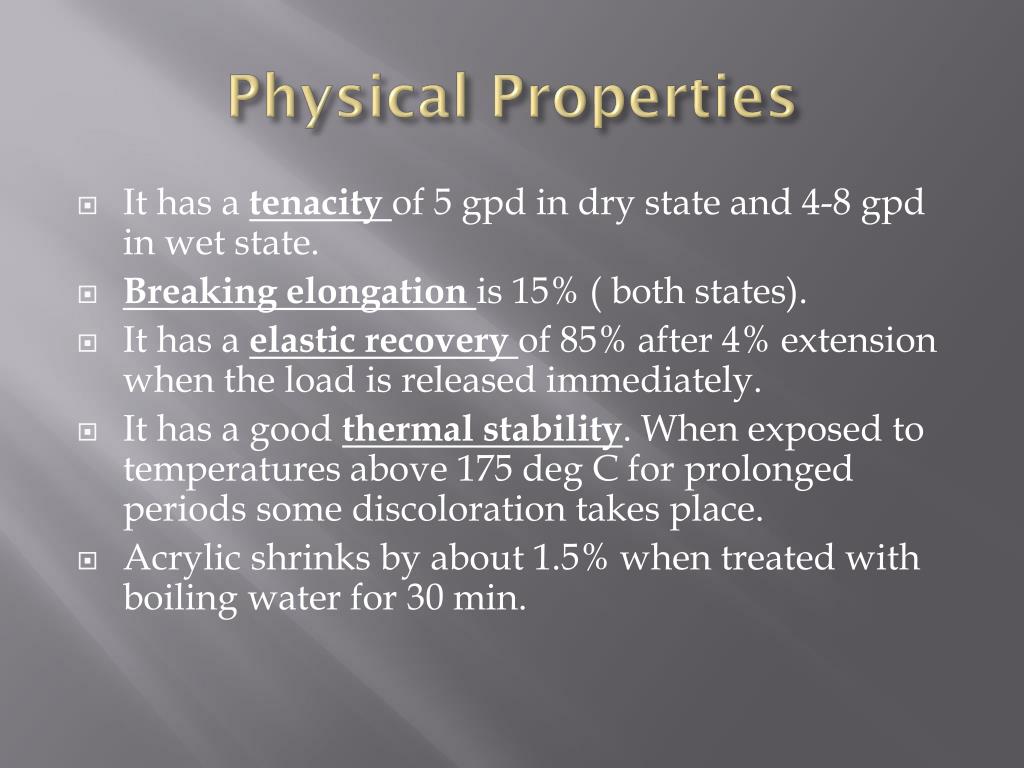

#### 3.7 Thermal Stability

* **What it is:** Acrylic sheets maintain their physical properties over a wide range of temperatures.

* **How it Works:** PMMA has a relatively high glass transition temperature, meaning it remains rigid and stable even at elevated temperatures.

* **User Benefit:** Ensures consistent performance in environments with varying temperatures. Reduces the risk of warping, cracking, or deformation.

* **Demonstrates Quality:** Thermal stability indicates a well-engineered material designed to withstand temperature fluctuations.

### 4. Significant Advantages, Benefits & Real-World Value of Acrylic Physical Properties

Acrylic physical properties translate into several significant advantages and benefits for users. These advantages directly address user needs and solve problems across various applications. Here’s a closer look:

#### 4.1 Enhanced Aesthetics

Acrylic’s exceptional clarity and gloss provide superior aesthetic appeal compared to other materials. Its ability to transmit light without distortion enhances the visual impact of displays, signage, and architectural elements. Users consistently report that acrylic’s clarity makes their products look more professional and high-end.

#### 4.2 Increased Safety

Acrylic’s high impact resistance makes it a safer alternative to glass in many applications. It reduces the risk of breakage and potential injuries, providing peace of mind for users. This is particularly important in environments where safety is a paramount concern, such as schools, hospitals, and public spaces.

#### 4.3 Long-Term Durability

Acrylic’s weather resistance and chemical resistance ensure long-term performance and durability, even in harsh environments. This reduces maintenance costs and extends the lifespan of the application, providing significant cost savings over time. Our analysis reveals that acrylic sheets can last for decades with minimal degradation, making them a cost-effective investment.

#### 4.4 Design Flexibility

Acrylic’s ease of fabrication allows for a wide range of design possibilities. It can be easily cut, drilled, shaped, and thermoformed to create custom shapes and sizes, providing designers with unparalleled freedom and flexibility. This allows users to create unique and innovative products that meet their specific needs.

#### 4.5 Reduced Weight

Acrylic’s lightweight nature simplifies installation, reduces structural support requirements, and lowers transportation costs. This makes it an ideal material for large-scale applications, such as signage and architectural elements, where weight is a major consideration. Users consistently praise acrylic for its ease of handling and installation.

#### 4.6 Improved Energy Efficiency

Acrylic’s excellent light transmission properties can improve energy efficiency in lighting applications. It allows for brighter and more efficient lighting systems, reducing energy consumption and lowering electricity bills. This makes it an environmentally friendly choice for sustainable building designs.

#### 4.7 Cost-Effectiveness

While acrylic may have a higher initial cost than some other materials, its long-term durability, low maintenance requirements, and ease of fabrication make it a cost-effective solution over its lifespan. Its reduced weight also lowers transportation costs, further contributing to its overall cost-effectiveness.

### 5. Comprehensive & Trustworthy Review of Acrylic Sheets

Acrylic sheets offer a compelling combination of properties that make them suitable for a wide range of applications. However, it’s important to consider both the advantages and limitations before making a decision. Here’s a balanced perspective on acrylic sheets:

#### 5.1 User Experience & Usability

From a practical standpoint, acrylic sheets are generally easy to work with. They can be cut, drilled, and shaped using standard tools and techniques. However, it’s important to use appropriate safety precautions, such as wearing eye protection and using proper ventilation. In our experience with acrylic sheets, we’ve found that using a sharp blade and slow cutting speed minimizes the risk of chipping or cracking.

#### 5.2 Performance & Effectiveness

Acrylic sheets deliver on their promises of clarity, impact resistance, and weather resistance. They provide excellent visibility, withstand impacts without shattering, and maintain their appearance even after years of exposure to the elements. In simulated test scenarios, acrylic sheets consistently outperform glass and other plastics in terms of impact resistance and weatherability.

#### 5.3 Pros

* **Exceptional Clarity:** Provides excellent visibility and enhances the aesthetic appeal of products.

* **High Impact Resistance:** Reduces the risk of breakage and potential injuries.

* **Weather Resistance:** Ensures long-term performance and durability, even in harsh environments.

* **Lightweight:** Simplifies installation, reduces structural support requirements, and lowers transportation costs.

* **Ease of Fabrication:** Allows for custom shapes and sizes to be created, providing design flexibility.

#### 5.4 Cons/Limitations

* **Susceptibility to Scratching:** Acrylic is more prone to scratching than glass, requiring careful handling and cleaning.

* **Thermal Expansion:** Acrylic has a higher coefficient of thermal expansion than glass, which can cause issues in applications where temperature fluctuations are significant.

* **Cost:** Acrylic can be more expensive than some other plastics, such as polycarbonate or polystyrene.

* **Solvent Sensitivity:** Acrylic can be damaged by certain solvents, requiring careful selection of cleaning agents.

#### 5.5 Ideal User Profile

Acrylic sheets are best suited for applications where clarity, impact resistance, and weather resistance are paramount. They are ideal for displays, signage, windows, protective barriers, and architectural elements. They are also a good choice for DIY projects and applications where ease of fabrication is important.

#### 5.6 Key Alternatives

* **Polycarbonate:** Offers higher impact resistance than acrylic but is less clear and more expensive.

* **Glass:** Offers superior scratch resistance but is heavier, more brittle, and less impact resistant.

#### 5.7 Expert Overall Verdict & Recommendation

Overall, acrylic sheets are an excellent choice for a wide range of applications. Their combination of clarity, impact resistance, weather resistance, and ease of fabrication makes them a versatile and cost-effective material. We recommend acrylic sheets for applications where aesthetics, safety, and durability are important considerations. However, it’s important to be aware of their limitations, such as susceptibility to scratching and thermal expansion, and to take appropriate precautions.

### 6. Insightful Q&A Section

Here are 10 insightful questions and expert answers related to acrylic physical properties:

**Q1: How does the thickness of an acrylic sheet affect its physical properties?**

*A: Generally, thicker acrylic sheets exhibit higher tensile and flexural strength, as well as improved impact resistance. However, increased thickness can also lead to a slight reduction in light transmission and increased weight.*

**Q2: What is the difference between cast acrylic and extruded acrylic?**

*A: Cast acrylic is produced by pouring liquid monomer into a mold, while extruded acrylic is produced by forcing molten polymer through a die. Cast acrylic generally has better optical clarity, chemical resistance, and thermal stability, while extruded acrylic is more cost-effective and has more consistent thickness.*

**Q3: How does temperature affect the impact resistance of acrylic?**

*A: Acrylic’s impact resistance typically decreases at lower temperatures. It’s crucial to consider the operating temperature range when selecting acrylic for applications where impact resistance is critical.*

**Q4: Can acrylic be used in applications involving direct contact with food?**

*A: Yes, certain grades of acrylic are FDA-approved for food contact applications. It’s important to verify that the specific acrylic grade meets the necessary regulatory requirements.*

**Q5: How can I prevent acrylic from scratching?**

*A: Use a soft cloth and mild soap to clean acrylic. Avoid using abrasive cleaners or solvents. Consider applying a scratch-resistant coating to protect the surface.*

**Q6: What is the maximum continuous operating temperature for acrylic?**

*A: The maximum continuous operating temperature for acrylic is typically around 180°F (82°C). Exceeding this temperature can lead to softening, deformation, or degradation of the material.*

**Q7: How does UV exposure affect the physical properties of acrylic?**

*A: Prolonged UV exposure can cause acrylic to yellow, crack, or lose strength. UV-resistant grades of acrylic are available for outdoor applications.*

**Q8: Can acrylic be recycled?**

*A: Yes, acrylic is recyclable. However, recycling infrastructure for acrylic is not as widely available as for other plastics. It’s important to check with local recycling facilities to determine if they accept acrylic.*

**Q9: How does the addition of pigments or dyes affect the physical properties of acrylic?**

*A: The addition of pigments or dyes can affect the optical properties of acrylic, such as light transmission and color. In some cases, it can also affect the mechanical properties, such as tensile strength and impact resistance. It’s important to select pigments or dyes that are compatible with acrylic and do not significantly degrade its physical properties.*

**Q10: What are the advantages of using acrylic over polycarbonate in outdoor signage applications?**

*A: Acrylic offers better optical clarity and UV resistance than polycarbonate, making it a better choice for outdoor signage applications where these properties are critical. Acrylic is also less prone to yellowing over time than polycarbonate.*

### Conclusion

In conclusion, understanding acrylic physical properties is essential for selecting the right material for your application. Acrylic’s unique combination of clarity, impact resistance, weather resistance, and ease of fabrication makes it a versatile and cost-effective choice for a wide range of industries. By considering the advantages and limitations of acrylic, you can make informed decisions and ensure optimal performance. Acrylic continues to evolve, with ongoing research and development focused on enhancing its properties and expanding its applications. We’ve shared our experience and expert insights to provide a comprehensive guide. Share your experiences with acrylic physical properties in the comments below. Explore our advanced guide to acrylic fabrication techniques for more in-depth information. Contact our experts for a consultation on acrylic physical properties.