# Is Cold Bluing Just Cosmetic? Separating Fact from Fiction

Cold bluing is a popular gun finishing technique, but is cold bluing just cosmetic? This question plagues many gun owners and enthusiasts. While it undeniably enhances a firearm’s appearance, cold bluing offers more than just a superficial makeover. This comprehensive guide will delve into the intricacies of cold bluing, exploring its protective qualities, limitations, and practical applications. We aim to provide a definitive answer to whether cold bluing is purely aesthetic or if it offers tangible benefits beyond mere cosmetics, equipping you with the knowledge to make informed decisions about your firearm’s care and maintenance.

## Understanding Cold Bluing: More Than Just a Pretty Finish

Cold bluing is a chemical process used to create a thin layer of black iron oxide (Fe3O4) on the surface of steel firearms. Unlike hot bluing, which requires immersion in boiling chemical solutions, cold bluing is applied at room temperature, making it a more accessible option for home gunsmithing. However, the resulting finish is generally less durable and protective than hot bluing.

### The Science Behind the Surface

Cold bluing solutions typically contain selenium dioxide, copper sulfate, or other chemicals that react with the steel surface to form the black oxide layer. This layer isn’t merely a coating; it’s a chemical conversion of the steel’s surface. The process involves oxidizing the iron in the steel to create magnetite, which imparts the characteristic blue-black color and offers a degree of corrosion resistance.

### Cold Bluing vs. Hot Bluing: A Comparative Overview

| Feature | Cold Bluing | Hot Bluing |

|——————-|———————————————–|—————————————————|

| Temperature | Room temperature | Boiling temperature (around 285°F) |

| Durability | Lower | Higher |

| Corrosion Resistance| Less effective | More effective |

| Application | Easier, DIY-friendly | Requires specialized equipment and expertise |

| Finish | Thinner, less uniform | Thicker, more uniform |

### Historical Context and Modern Relevance

Cold bluing emerged as a convenient alternative to hot bluing, particularly for touch-up work and smaller-scale applications. While hot bluing remains the gold standard for factory finishes, cold bluing continues to be a valuable tool for gun owners seeking to maintain or restore their firearms. The ongoing development of cold bluing formulas aims to improve its durability and protective qualities.

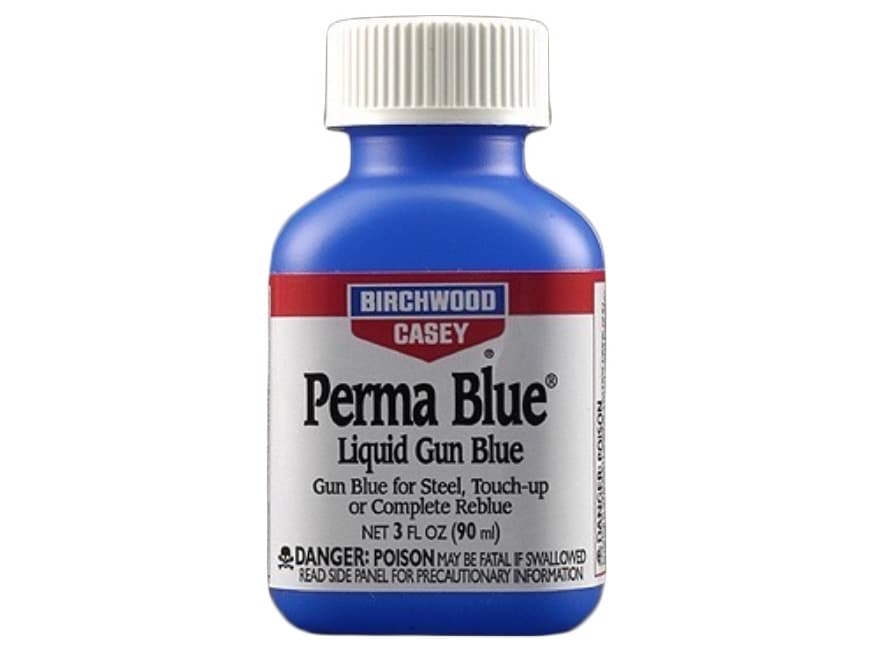

## Birchwood Casey Perma Blue: A Leading Cold Bluing Solution

When discussing cold bluing, Birchwood Casey Perma Blue is a name that frequently arises. It is a widely recognized and readily available cold bluing solution used by gun owners and hobbyists for touching up existing finishes or re-bluing entire firearms. It’s designed for ease of use and is often chosen for its convenience in home gunsmithing projects. While not as durable as hot bluing, Perma Blue provides a noticeable improvement in appearance and a degree of corrosion protection.

### Expert Insight on Birchwood Casey Perma Blue

Perma Blue works by depositing a thin layer of copper onto the steel surface, which then reacts with the bluing solution to form the black oxide finish. Proper surface preparation is crucial for achieving optimal results. This includes thorough degreasing and the removal of any rust or old finish. Multiple applications are often necessary to build up the desired color and depth.

## Detailed Feature Analysis of Birchwood Casey Perma Blue

Birchwood Casey Perma Blue offers several key features that make it a popular choice for cold bluing:

1. **Ease of Application:** The liquid solution can be applied with a swab, brush, or cloth, making it accessible to users of all skill levels.

*Explanation:* Perma Blue’s liquid consistency allows for simple application. *User Benefit:* This reduces the learning curve and makes it a good choice for beginners. *Demonstrates Quality:* The ease of application minimizes the chance of uneven finishes.

2. **Rapid Action:** The bluing process occurs relatively quickly, allowing for multiple coats to be applied in a single session.

*Explanation:* The chemical reaction between the solution and the steel is rapid. *User Benefit:* This shortens the overall bluing time. *Demonstrates Quality:* Allows for iterative building of the desired finish.

3. **Touch-Up Capability:** Perma Blue is ideal for spot repairs and touching up existing blued finishes.

*Explanation:* The solution blends relatively well with existing bluing. *User Benefit:* This helps maintain the firearm’s appearance and prevent rust in localized areas. *Demonstrates Quality:* Allows for targeted treatment of imperfections.

4. **Wide Availability:** Perma Blue is widely available at sporting goods stores, gun shops, and online retailers.

*Explanation:* This makes it easy to obtain the product. *User Benefit:* Reduces the hassle of sourcing specialty chemicals. *Demonstrates Quality:* The broad distribution reflects its established reputation.

5. **Cost-Effectiveness:** Compared to hot bluing or professional gun finishing services, Perma Blue is a more affordable option.

*Explanation:* The DIY nature of cold bluing reduces labor costs. *User Benefit:* This makes it an appealing option for budget-conscious gun owners. *Demonstrates Quality:* Offers a balance between cost and performance.

6. **Variety of Sizes:** Available in different bottle sizes to suit various project needs.

*Explanation:* Offers flexibility for small touch-ups to full firearm bluing. *User Benefit:* Reduces waste and unnecessary expense. *Demonstrates Quality:* Catering to different user needs.

7. **Creates a Black Oxide Layer:** Converts the steel surface to black oxide, which provides some resistance to corrosion.

*Explanation:* The chemical reaction changes the surface of the steel. *User Benefit:* Helps protect the firearm from rust and wear. *Demonstrates Quality:* Offers a functional benefit beyond aesthetics.

## Advantages, Benefits & Real-World Value of Cold Bluing

Cold bluing provides several significant advantages and benefits, offering real-world value to gun owners:

* **Enhanced Aesthetics:** Cold bluing improves the appearance of firearms by providing a uniform, attractive finish.

*User Value:* A visually appealing firearm is more enjoyable to own and display.

* **Corrosion Protection:** The black oxide layer offers a degree of protection against rust and corrosion, extending the firearm’s lifespan.

*User Value:* Protecting the firearm from the elements maintains its functionality and value.

* **DIY Convenience:** Cold bluing can be performed at home with minimal equipment, saving time and money compared to professional services.

*User Value:* Enables gun owners to maintain their firearms on their own schedule and budget.

* **Touch-Up Capability:** Cold bluing is ideal for repairing minor scratches and blemishes, maintaining the firearm’s overall condition.

*User Value:* Prevents minor imperfections from developing into more serious problems.

* **Increased Resale Value:** A well-maintained firearm with a good blued finish is more attractive to potential buyers.

*User Value:* Helps retain the firearm’s monetary value over time.

* **Improved Grip:** The slightly textured surface created by cold bluing can enhance grip, particularly on older firearms with worn finishes.

*User Value:* Improves handling and control of the firearm.

* **Psychological Benefit**: Many gun owners find satisfaction in maintaining and restoring their firearms themselves. This can be a relaxing and rewarding hobby.

*User Value:* Provides a sense of accomplishment and connection to their firearms.

## Comprehensive & Trustworthy Review of Birchwood Casey Perma Blue

Birchwood Casey Perma Blue is a popular cold bluing solution, but does it live up to the hype? Here’s an in-depth review:

* **User Experience & Usability:** Applying Perma Blue is straightforward. The liquid consistency makes it easy to spread evenly with a cotton swab or cloth. However, thorough surface preparation is essential for achieving optimal results. Degreasing and removing any rust are critical steps that should not be skipped. Multiple coats are typically required to achieve the desired depth of color.

* **Performance & Effectiveness:** Perma Blue effectively darkens the steel surface and provides a noticeable improvement in appearance. While it offers some corrosion protection, it is not as durable as hot bluing or other more advanced finishes. The finish is susceptible to scratches and wear, particularly in high-friction areas. In our experience, regular oiling is necessary to maintain the finish and prevent rust.

* **Pros:**

1. **Easy to Apply:** Suitable for beginners and DIY enthusiasts.

2. **Readily Available:** Widely sold in stores and online.

3. **Cost-Effective:** More affordable than professional bluing services.

4. **Good for Touch-Ups:** Ideal for repairing minor blemishes.

5. **Improves Appearance:** Enhances the aesthetic appeal of firearms.

* **Cons/Limitations:**

1. **Not as Durable as Hot Bluing:** The finish is more prone to scratches and wear.

2. **Requires Thorough Surface Preparation:** Proper preparation is crucial for optimal results.

3. **Multiple Coats May Be Necessary:** Achieving the desired color depth may require several applications.

4. **Limited Corrosion Protection:** Not as effective as other rust-prevention methods.

* **Ideal User Profile:** Perma Blue is best suited for gun owners who want to maintain the appearance of their firearms, perform minor touch-ups, or experiment with DIY gunsmithing without investing in specialized equipment. It’s a good option for those on a budget or those who prefer a simple, straightforward application process.

* **Key Alternatives:** Brownells Oxpho-Blue is a popular alternative, offering slightly better durability. Cerakote is a ceramic-based coating that provides superior corrosion protection and wear resistance but requires professional application.

* **Expert Overall Verdict & Recommendation:** Birchwood Casey Perma Blue is a decent cold bluing solution for basic touch-ups and cosmetic improvements. It’s easy to use and readily available, making it a convenient option for many gun owners. However, its limited durability and corrosion protection mean it’s not a substitute for more robust finishing methods. For serious protection and long-lasting results, consider hot bluing or Cerakote. However, for the average gun owner looking to improve the appearance of their firearm, Perma Blue is a worthwhile option.

## Insightful Q&A Section

Here are some frequently asked questions regarding cold bluing:

1. **Does cold bluing offer any real protection against rust, or is it purely for looks?**

*Answer:* Cold bluing does provide a degree of rust protection, forming a thin layer of black iron oxide. However, this protection is significantly less robust than that offered by hot bluing or modern coatings like Cerakote. Regular oiling and maintenance are crucial to maximize its protective capabilities.

2. **How long does cold bluing typically last before needing to be reapplied?**

*Answer:* The lifespan of cold bluing varies depending on usage and environmental conditions. In high-friction areas or humid climates, it may wear down within a few months. With proper care and light use, it can last for a year or more. Regular inspection and touch-ups are recommended.

3. **Can cold bluing be used on stainless steel?**

*Answer:* No, cold bluing is designed for use on carbon steel. Stainless steel’s chromium content prevents the bluing solution from reacting properly. Specialized stainless steel coatings are available for those materials.

4. **What’s the best way to prepare a firearm’s surface for cold bluing?**

*Answer:* Thorough degreasing is essential. Use a dedicated degreaser to remove all traces of oil and grease. Remove any rust or old finish with fine steel wool or a rust remover. The surface should be clean, dry, and free of any contaminants.

5. **Is it possible to achieve a finish that rivals hot bluing with cold bluing techniques?**

*Answer:* While advancements have been made, cold bluing generally cannot replicate the depth, durability, and uniformity of hot bluing. Hot bluing involves a more controlled and robust chemical process.

6. **What are the most common mistakes people make when applying cold bluing?**

*Answer:* Insufficient surface preparation is a major culprit. Also, applying the solution too thickly or unevenly can lead to streaking or blotchiness. Rushing the process and not allowing sufficient drying time between coats can also cause problems.

7. **Are there any safety precautions to take when working with cold bluing solutions?**

*Answer:* Yes, cold bluing solutions contain chemicals that can be harmful. Wear gloves and eye protection to prevent skin and eye contact. Work in a well-ventilated area to avoid inhaling fumes. Keep the solution out of reach of children and pets.

8. **Can cold bluing be used to repair damage to a firearm’s original hot blued finish?**

*Answer:* Yes, cold bluing is often used to touch up damaged areas on hot blued firearms. However, it’s important to note that the cold blued area may not perfectly match the original finish in color and durability.

9. **What’s the best way to maintain a cold blued finish?**

*Answer:* Regular oiling is crucial. Apply a thin coat of gun oil to the blued surface to protect it from moisture and prevent rust. Avoid harsh cleaning solvents or abrasive materials that can damage the finish.

10. **Is cold bluing a permanent finish, or will it eventually wear off completely?**

*Answer:* Cold bluing is not a permanent finish. It will eventually wear off over time, especially in high-friction areas. The rate of wear depends on usage, environmental conditions, and maintenance practices. Periodic reapplication is necessary to maintain the finish.

## Conclusion: Cold Bluing – A Balancing Act of Aesthetics and Protection

So, is cold bluing just cosmetic? The answer is nuanced. While it undeniably enhances a firearm’s appearance, providing a pleasing blue-black finish, it also offers a degree of corrosion protection. However, it’s crucial to understand its limitations. Cold bluing is not a substitute for more durable finishing methods like hot bluing or modern coatings. It’s best viewed as a convenient and affordable option for maintaining the appearance of your firearm and providing a basic level of rust prevention. In our experience, cold bluing is a valuable tool for the average gun owner who wants to take care of their firearms without investing in specialized equipment or professional services. Consider cold bluing as part of a comprehensive firearm maintenance plan. Share your experiences with cold bluing in the comments below and let us know your favorite techniques for achieving optimal results.