# Reactivity Ratios of Acrylic Monomers: A Comprehensive Guide to Polymer Design

Reactivity ratios of acrylic monomers are crucial parameters in copolymerization, dictating the microstructure and properties of the resulting polymer. Understanding and controlling these ratios is essential for designing polymers with specific characteristics, such as improved mechanical strength, thermal stability, or chemical resistance. This article provides an in-depth exploration of reactivity ratios for acrylic monomers, covering their significance, determination, influencing factors, and applications in polymer science and engineering. We aim to equip you with the knowledge to effectively utilize these ratios in your polymer design endeavors.

## Understanding Reactivity Ratios: The Foundation of Copolymerization

Copolymerization involves the polymerization of two or more different monomers. Unlike homopolymers, which consist of repeating units of a single monomer, copolymers exhibit a more complex structure due to the varying incorporation rates of each monomer. Reactivity ratios quantify these relative incorporation rates, providing valuable insights into the copolymerization process.

### Definition and Significance

The reactivity ratio (r) for a given monomer in a copolymerization system is defined as the ratio of the rate constant for a monomer adding to a polymer chain ending with the same monomer to the rate constant for the monomer adding to a polymer chain ending with the other monomer. For a two-monomer system (monomers A and B), there are two reactivity ratios:

* **rA = kAA / kAB:** Where kAA is the rate constant for monomer A adding to a polymer chain ending in monomer A, and kAB is the rate constant for monomer A adding to a polymer chain ending in monomer B.

* **rB = kBB / kBA:** Where kBB is the rate constant for monomer B adding to a polymer chain ending in monomer B, and kBA is the rate constant for monomer B adding to a polymer chain ending in monomer A.

These ratios provide information about the preference of a propagating chain end for adding its own monomer versus the other monomer present in the system. For example, if rA > 1, monomer A preferentially adds to a chain ending in monomer A, promoting the formation of longer sequences of monomer A units. Conversely, if rA > 1, rB >> 1):** Both monomers strongly prefer to add to their own chain ends, resulting in long sequences (blocks) of each monomer. The resulting copolymer consists of distinct blocks of A and B units.

### Importance of Accurate Reactivity Ratio Determination

Accurate determination of reactivity ratios is crucial for several reasons:

* **Predicting Copolymer Composition:** Reactivity ratios allow us to predict the composition of the copolymer formed at a given monomer feed ratio. This is essential for tailoring the copolymer properties to specific applications.

* **Controlling Copolymer Microstructure:** By manipulating the reactivity ratios (e.g., through the choice of monomers, reaction conditions, or additives), we can control the microstructure of the copolymer, influencing its properties.

* **Optimizing Polymerization Processes:** Reactivity ratios can be used to optimize polymerization processes, such as minimizing composition drift and achieving high monomer conversion.

## Acrylic Monomers: A Versatile Class of Building Blocks

Acrylic monomers are a class of unsaturated organic compounds derived from acrylic acid (CH2=CHCOOH) or methacrylic acid (CH2=C(CH3)COOH). They are widely used in the production of various polymers and copolymers due to their versatility, reactivity, and ability to impart desirable properties to the resulting materials.

### Common Acrylic Monomers

Some of the most common acrylic monomers include:

* **Methyl Methacrylate (MMA):** A widely used monomer for producing PMMA (Plexiglas), known for its clarity, rigidity, and weather resistance.

* **Ethyl Acrylate (EA):** Provides flexibility and impact resistance to polymers.

* **Butyl Acrylate (BA):** Similar to EA, but offers even greater flexibility and lower glass transition temperature (Tg).

* **Acrylic Acid (AA):** Introduces hydrophilicity and adhesion properties to polymers.

* **Methacrylic Acid (MAA):** Similar to AA, but with enhanced hardness and thermal stability.

* **Acrylonitrile (AN):** Imparts chemical resistance and barrier properties.

### Reactivity Differences Among Acrylic Monomers

Acrylic monomers exhibit a wide range of reactivity depending on their chemical structure. Factors such as the presence of substituents on the double bond (e.g., methyl group in methacrylates) and the nature of the ester group influence their reactivity in copolymerization.

For instance, methacrylates are generally less reactive than acrylates due to steric hindrance from the methyl group. Similarly, monomers with electron-withdrawing substituents tend to be more reactive than those with electron-donating substituents.

### Reactivity Ratios of Common Acrylic Monomer Pairs

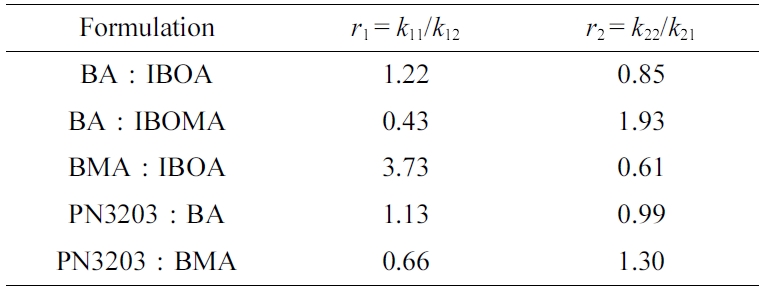

Understanding the reactivity ratios of different acrylic monomer pairs is essential for designing copolymers with desired properties. Here are some examples:

* **MMA/EA:** MMA is generally more reactive than EA. Reactivity ratios depend on the polymerization technique, but typically rMMA > 1 and rEA < 1.

* **BA/Styrene:** BA is less reactive than styrene. Reactivity ratios are rBA 1.

* **AA/EA:** AA is more reactive than EA. Reactivity ratios are rAA > 1 and rEA 1 and rBA < 1). This means that MMA will be incorporated into the copolymer at a faster rate than BA, leading to a copolymer that is richer in MMA than the monomer feed.

To compensate for this difference in reactivity, it is necessary to use a higher proportion of BA in the monomer feed. The exact proportion will depend on the desired copolymer composition and the specific reactivity ratios of MMA and BA under the chosen reaction conditions. Experimental trials can be conducted to determine the optimal monomer feed ratio for achieving the desired impact resistance.

## Expert Insights: Overcoming Challenges in Reactivity Ratio Determination

Determining accurate reactivity ratios can be challenging due to several factors, including experimental errors, complex reaction kinetics, and the limitations of the available analytical techniques. Here are some expert insights for overcoming these challenges:

* **Use High-Purity Monomers:** Impurities in the monomers can affect the polymerization kinetics and lead to inaccurate reactivity ratio determinations. Use high-purity monomers and purify them if necessary.

* **Control Reaction Conditions Carefully:** Temperature, solvent, and initiator concentration can all affect the reactivity ratios. Control these parameters carefully and maintain them constant throughout the polymerization.

* **Use Multiple Analytical Techniques:** Use multiple analytical techniques to determine the copolymer composition, such as NMR spectroscopy, GPC, and elemental analysis. Compare the results obtained from different techniques to ensure consistency.

* **Use Statistical Methods:** Use statistical methods, such as nonlinear least-squares regression, to analyze the experimental data and estimate the reactivity ratios. These methods can account for experimental errors and provide more accurate estimates of the reactivity ratios.

## Q&A: Deep Dive into Reactivity Ratios of Acrylic Monomers

**Q1: How does the presence of a bulky substituent on an acrylic monomer affect its reactivity ratio?**

*Answer:* Bulky substituents, like the methyl group in methacrylates, generally decrease the monomer's reactivity due to steric hindrance. This makes it more difficult for the monomer to approach the active site of the propagating polymer chain, leading to a lower reactivity ratio. This effect is more pronounced when the substituent is close to the polymerizable double bond.

**Q2: What are the limitations of using the Fineman-Ross method for determining reactivity ratios?**

*Answer:* The Fineman-Ross method is a linearization technique prone to inaccuracies because it gives undue weight to data points at extreme monomer feed ratios, where experimental errors are often larger. It also assumes that the reactivity ratios are constant over the entire range of monomer compositions, which may not always be the case.

**Q3: Can reactivity ratios be used to predict the sequence distribution of monomers in a copolymer?**

*Answer:* Yes, reactivity ratios are key to predicting sequence distribution. They provide information on the probability of a monomer adding to a chain ending in the same or different monomer. This allows for the calculation of various sequence statistics, such as the average sequence length of each monomer and the degree of alternation in the copolymer.

**Q4: How does the choice of initiator affect reactivity ratios in free radical polymerization?**

*Answer:* The initiator itself doesn't directly affect the reactivity ratios. However, the initiator can influence the overall polymerization rate and the concentration of radicals in the system. If the polymerization rate is very high, it can lead to a Trommsdorff effect (gel effect), which can alter the apparent reactivity ratios due to changes in the viscosity of the reaction medium.

**Q5: What is the significance of a negative reactivity ratio?**

*Answer:* A negative reactivity ratio is theoretically impossible. It would imply that a monomer preferentially reacts with a chain ending in itself less often than randomly expected, which is not physically realistic. In practice, negative values obtained from experimental data analysis usually indicate significant experimental errors or an inappropriate model for the system.

**Q6: How does the use of a chain transfer agent influence the determination of reactivity ratios?**

*Answer:* Chain transfer agents can complicate the determination of reactivity ratios by introducing additional reactions that affect the molecular weight and composition of the copolymer. If chain transfer is significant, it's important to account for it in the kinetic model used to analyze the experimental data. Otherwise, the determined reactivity ratios may be inaccurate.

**Q7: What are some advanced techniques for determining reactivity ratios beyond traditional methods?**

*Answer:* Advanced techniques include pulsed-laser polymerization (PLP) coupled with size-exclusion chromatography (SEC), which allows for the determination of propagation rate coefficients for each monomer. Also, computational methods like Density Functional Theory (DFT) can estimate reactivity ratios by calculating the activation energies of monomer addition reactions.

**Q8: How do hydrogen bonding interactions between monomers affect reactivity ratios in copolymerization?**

*Answer:* Hydrogen bonding can significantly influence reactivity ratios, especially in monomers like acrylic acid. Hydrogen bonding can lead to self-association of monomers, affecting their local concentration and reactivity. It can also influence the conformation of the propagating chain end, altering its selectivity towards different monomers.

**Q9: In emulsion polymerization, how do the partitioning of monomers between the aqueous and organic phases affect the apparent reactivity ratios?**

*Answer:* In emulsion polymerization, monomers are partitioned between the aqueous and organic phases (micelles). If the monomers have different partition coefficients, their local concentrations within the micelles will differ from the overall feed ratio. This can lead to apparent reactivity ratios that are different from the true values. It's important to consider this partitioning effect when analyzing data from emulsion polymerizations.

**Q10: How can the addition of a third monomer (terpolymerization) influence the reactivity of the other two monomers?**

*Answer:* Adding a third monomer introduces additional interactions and reaction pathways, which can significantly alter the apparent reactivity ratios of the other two monomers. The third monomer can preferentially react with one or both of the original monomers, changing their relative incorporation rates into the polymer chain. The reactivity ratios in terpolymerization are more complex and require more sophisticated models for accurate determination.

## Conclusion: Mastering Reactivity Ratios for Polymer Innovation

Understanding and controlling the reactivity ratios of acrylic monomers is paramount for designing polymers with tailored properties. By carefully considering the factors that influence these ratios and employing appropriate experimental and computational techniques, polymer scientists and engineers can create innovative materials for a wide range of applications. From coatings and adhesives to plastics and biomedical materials, the ability to manipulate copolymer microstructure through reactivity ratio control unlocks endless possibilities for polymer innovation. We encourage you to further explore the intricacies of reactivity ratios in your own research and development endeavors. Share your experiences with reactivity ratios acrylic monomers in the comments below, or contact our experts for a consultation on reactivity ratios acrylic monomers.